How Táche Improved Inventory Accuracy While Reducing Manual Tasks by Over 60%

Manual Tasks

Quick Summary

The Brand:

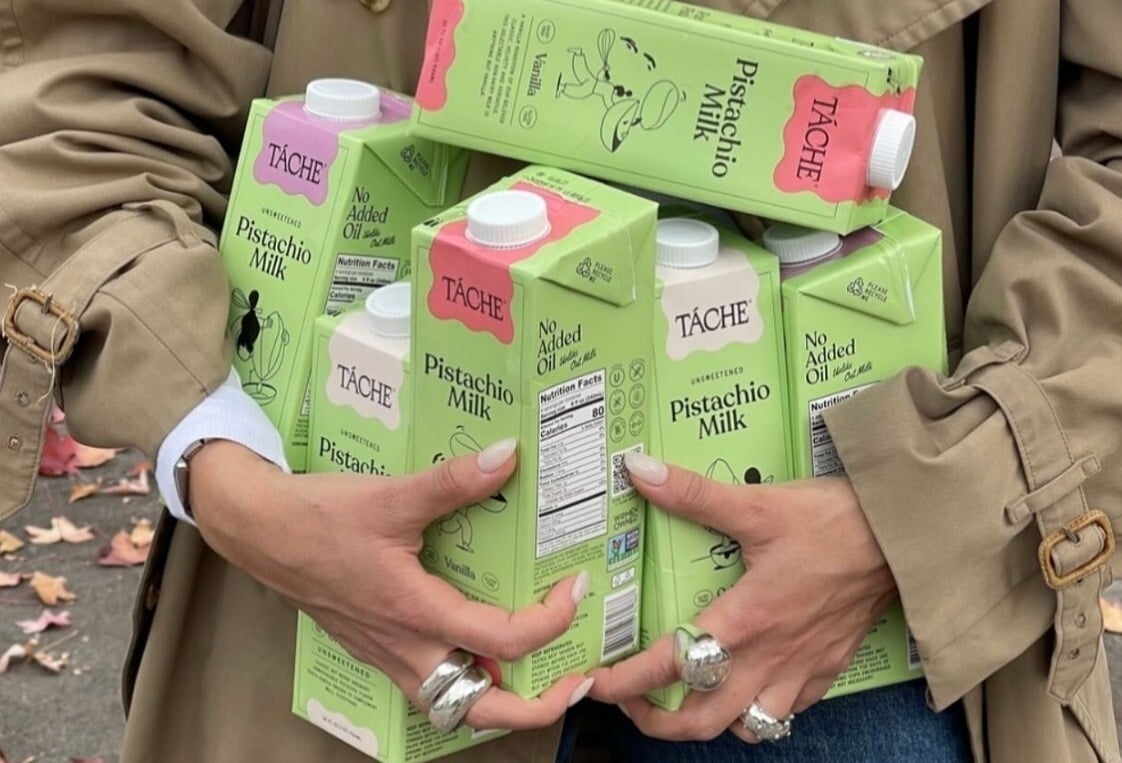

Tache is the first pistachio milk in the U.S., launched in 2020 as a sustainable, nutritious milk alternative. In just a few years, the New York-based brand has expanded into Whole Foods, Target, Erewhon, and cafes nationwide.

The Challenge:

As orders grew across both retail and DTC channels, Tache’s lean operations team struggled to keep up. Their previous 3PL created more headaches than solutions, leaving the brand in need of a reliable logistics partner.

The Solution:

Smart Warehousing incorporated EDI integrations which reduced the manual workload for Tache’s small team as well as created a predictable workflow. Alongside advanced integrations, consistent fulfillment, and clear SOPs, Tache gained the operational stability it needed to grow without being overwhelmed.

The Result:

Order accuracy improved to 99%, inventory issues were virtually eliminated, and inbound processing times dropped by 90%. With reliable fulfillment and communication in place, Tache has grown 300% without added operational strain.

Tache's Story

What started as a sustainable, homemade alternative to almond milk, led to the launch of Tache in 2020. Tache, the first true pistachio milk in the U.S., emerged as a family-inspired recipe into a health-conscious product reshaping how consumers think about plant-based milk. Crafted with pistachios sourced from a fourth-generation family farm and requiring 75% less water to produce compared to almonds, this dairy-free milk combines nutrition, bold flavor, and sustainability.

In just a few short years, the New York-based company has grown from a kitchen experiment into a nationally recognized brand, now found in Whole Foods, Target, Erewhon, and cafes across the country. With this nationwide growth came a new set of logistical challenges.

As a one-man operations team and experiencing increasing orders across both retail and DTC channels, Tache needed a fulfillment partner who could take the stress out of scaling as well as handle the level of demand.

The Challenge

Before partnering with Smart Warehousing, Tache worked with another 3PL where the partnership fell short of expectations. Inventory inaccuracies, incorrectly packed orders, missed SLAs, and even lost pallets were a daily struggle. The average dock-to-stock time took anywhere between 7-14 days, resulting in incredibly slow order processing and longer delivery times. These operational missteps not only upset customers but also created constant stress on Tache’s small team. Beyond the mistakes themselves, the previous provider failed to communicate proactively, leaving Tache in the dark on critical issues and forcing Tache to spend countless hours fixing problems that shouldn’t have existed in the first place.

Dealing with these significant backend issues had an incredible impact on Tache’s reputation. Customers were upset, orders were being canceled, and the internal (one-man) team was forced to spend valuable time troubleshooting basic operational mistakes instead of focusing on growth.

The Search

Frustrated with their existing 3PL, Tache began looking for a provider that could meet their needs. Through a mix of a 3PL finder service and word-of-mouth, they heard repeated recommendations for Smart Warehousing.

“

We were looking for a partner that was as open and honest as possible, and you guys hit the nail on the head with that.”– Mike Van Dorn, Vice President of Operations and Finance

“We visited Smart’s warehouse and two or three other potential partners as well, and I think that was really what sealed the deal. There was just a level of calm, frankly, that was emanating out of the warehouse where I did not get that feeling at others,” Mike recalled.

Communication and structure were at the top of Tache’s wish list. Smart’s reputation for strict SOPs, accurate processes, and upfront, transparent communication aligned perfectly with what Tache needed to move forward.

The Solution

Smart Warehousing hit the ground running, making the transition effortless from day one. “It was a very smooth onboarding process. Implementation went as smoothly as it could have been. We’re seeing benefits on our side where we’re saving time, resources and money,” Mike expressed.

Smart immediately closed the gaps Tache had struggled with for years. By integrating directly with their ERP systems, Smart automated inventory and accounting tasks, eliminating over 60% of Tache’s manual tasks and saving them hours of work for a one-person team. “We have not needed to hire any additional operations headcount since transitioning to Smart and leveraging Smart’s tech integrations. This alone has been an incredibly important piece for us,” Mike explained.

Beyond technology, Smart’s strict SOPs and clearly defined cut-offs created a predictable workflow for daily operations. With a responsive support team in place, Tache could count on answers and solutions daily. Smart’s combination of advanced technology, decades of experience, and a highly skilled workforce provided the operational backbone Tache had been missing.

With SWIMS, Smart’s proprietary warehouse management system, Tache no longer had to rely on third-party systems. Mike states, “It’s nice to know that SWIMS is your platform and if there’s ever an issue, it’s all handled internally rather than relying on a third party.”

The Results

The impact of partnering with Smart Warehousing was immediate. Tache was able to receive product on day one and begin shipping on day two – a stark contrast to prior experiences where delays had become the norm. Order accuracy quickly jumped to 99%, eliminating weekly issues that once drained valuable time and resources. Inventory management has also shifted from experiencing multiple inventory issues on a weekly basis to now a nearly flawless inventory.

The improvements extended to inbound processes as well. What previously took 7-14 days was reduced to just 24 hours, giving Tache the speed needed to keep pace with retailer demand.

Most importantly, Tache has been able to scale without the stress and operational strain. Since transitioning to Smart, Tache has grown nearly 300%, all while avoiding logistical hurdles that typically come with expansion. “We have been able to handle this growth seamlessly without growing pains. Smart’s team has been able to grow with us and adapt to our needs. At no point have we felt stifled in our growth,” Mike notes.

A Partnership Centered Around Trust

Tache credits the partnership with Smart Warehousing not only for operational improvements, but also for the confidence and trust it brings to the business. Mike voices, “The biggest improvements from switching to Smart has been consistency. If there are issues or questions, I know exactly who to call and I always get an answer. There’s always that level of stability which is invaluable.”

Today, Tache can focus on what matters most: expanding the brand and delivering a product that customers love. The relationship with Smart Warehousing has transformed logistics from a constant source of stress into a strategic asset, allowing Tache to grow without being weighed down by operational headaches.

Mike says, “When speaking with other brands, it feels like we’re the outlier because we genuinely have good things to say about our warehousing partner. It’s something we really value and don’t take for granted.”